You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Studio Treatment Thread

- Thread starter TJontheRoad

- Start date

TJontheRoad

Shredder

- Messages

- 1,214

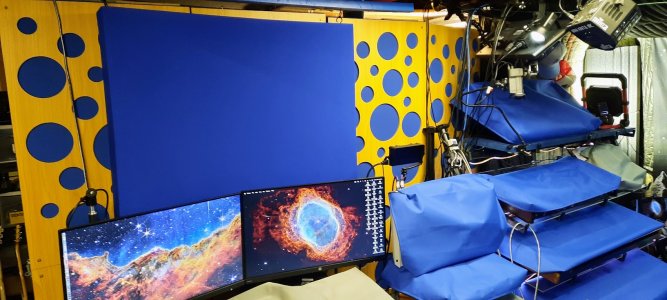

Update: This weekend, I installed the black ceiling acoustic panels and LED lighting. There's 8 LED lights and each have individual remote on/off switches that I wired receivers on to their electrical control boxes. I can change the lighting from a single LED to all 8 on super bright whenever the mood strikes me.

Attachments

TJontheRoad

Shredder

- Messages

- 1,214

Last part is in route. Two of these portable isolation walls/booths. They'll sit on the back wall and also will be used for vocal or acoustic guitar recording when needed.

www.gikacoustics.com

www.gikacoustics.com

PIB (Portable Isolation Booth) Vocal Booth and Instrument Booth - GiK Acoustics

Our portable isolation booth or vocal booth provides sound isolation with quality performance. Perfect for artists looking to significantly improve recording quality in any room. Its folding design makes it versatile enough to take with you anywhere, and makes an attractive addition to any...

www.gikacoustics.com

www.gikacoustics.com

TJontheRoad

Shredder

- Messages

- 1,214

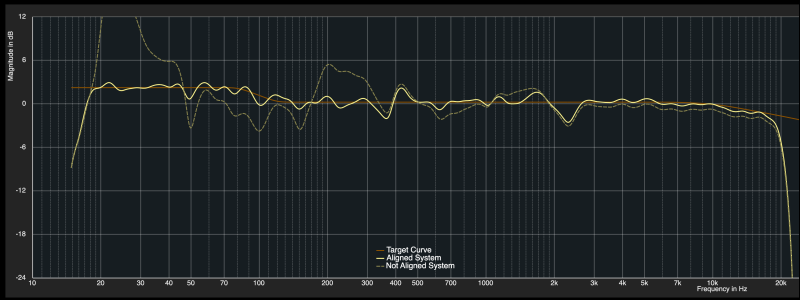

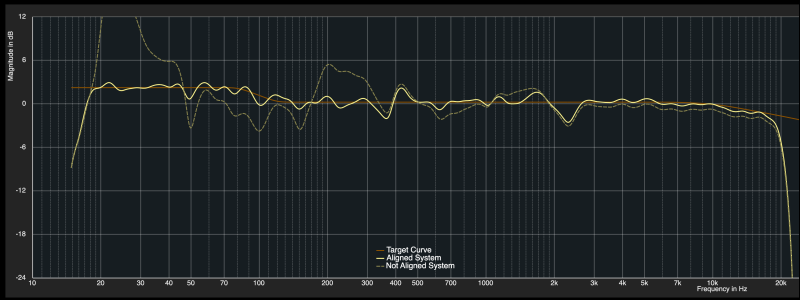

Last update. Rear PIB panels installed. Room measurements completed and then corrections done with the Neumann MA 1 software. 1st screenshot shows initial measurements and auto alignment. 2nd screenshot shows corrections applied. A couple minor dips in the final aligned system curve, but pretty flat otherwise.

The whole room with the KH-150s sounds fantastic now. I'm very pleased

The whole room with the KH-150s sounds fantastic now. I'm very pleased

Attachments

Jarick

Rock Star

- Messages

- 5,004

I'm getting the supplies to make acoustic panels tonight! Been meaning to do it for oh 20 years or so.

Big thing I've learned is how much my perceived issues with certain speakers is related to my room. Using the IK Arc correction, my speakers sound way better. I'm really interested to see how much more improvement I can get cleaning up the low end and reducing reverberation with proper treatment.

I'm planning to get some mineral wool insulation and 1x4's from the local hardware store, and then covering with canvas cloth from the fabric store. It won't be as effective as the mail order stuff but should help quite a bit. I'm going to make ten 15" x 47" panels.

Big thing I've learned is how much my perceived issues with certain speakers is related to my room. Using the IK Arc correction, my speakers sound way better. I'm really interested to see how much more improvement I can get cleaning up the low end and reducing reverberation with proper treatment.

I'm planning to get some mineral wool insulation and 1x4's from the local hardware store, and then covering with canvas cloth from the fabric store. It won't be as effective as the mail order stuff but should help quite a bit. I'm going to make ten 15" x 47" panels.

Boudoir Guitar

Rock Star

- Messages

- 5,255

If you're able to rip plywood, I'd suggest going with plywood over 1x4s -- the 1x4s will work, but assuming your room has pretty decent humidity swings, the 1x4s will move a bit. Not enough to fail or anything, but CAN look a little wonky. And plywood would be cheaper. But either should work. Get lots of staples for the staple gun. Good luck! Totally worth the work/modest cash outlay.I'm getting the supplies to make acoustic panels tonight! Been meaning to do it for oh 20 years or so.

Big thing I've learned is how much my perceived issues with certain speakers is related to my room. Using the IK Arc correction, my speakers sound way better. I'm really interested to see how much more improvement I can get cleaning up the low end and reducing reverberation with proper treatment.

I'm planning to get some mineral wool insulation and 1x4's from the local hardware store, and then covering with canvas cloth from the fabric store. It won't be as effective as the mail order stuff but should help quite a bit. I'm going to make ten 15" x 47" panels.

Jarick

Rock Star

- Messages

- 5,004

If you're able to rip plywood, I'd suggest going with plywood over 1x4s -- the 1x4s will work, but assuming your room has pretty decent humidity swings, the 1x4s will move a bit. Not enough to fail or anything, but CAN look a little wonky. And plywood would be cheaper. But either should work. Get lots of staples for the staple gun. Good luck! Totally worth the work/modest cash outlay.

Definitely thought about it! But I don't have a table saw yet to rip plywood, just a circular saw to cut down boards. Usually with each project I use that as an excuse to start building up my tool collection, but I need to clean out my garage before I can have room for adding more stuff (although I am going to pick up a jigsaw today). Also, humidity should be good here as I have a dehumidifier in my basement which keeps things pretty consistent (we had moisture issues when we moved in).

- Messages

- 10,125

Honestly, I used a jigsaw to make mine!!! The wood is covered. Doesn't need to be pretty.Definitely thought about it! But I don't have a table saw yet to rip plywood, just a circular saw to cut down boards. Usually with each project I use that as an excuse to start building up my tool collection, but I need to clean out my garage before I can have room for adding more stuff (although I am going to pick up a jigsaw today). Also, humidity should be good here as I have a dehumidifier in my basement which keeps things pretty consistent (we had moisture issues when we moved in).

Boudoir Guitar

Rock Star

- Messages

- 5,255

Sounds like you've got a plan. For future reference:Definitely thought about it! But I don't have a table saw yet to rip plywood, just a circular saw to cut down boards. Usually with each project I use that as an excuse to start building up my tool collection, but I need to clean out my garage before I can have room for adding more stuff (although I am going to pick up a jigsaw today). Also, humidity should be good here as I have a dehumidifier in my basement which keeps things pretty consistent (we had moisture issues when we moved in).

Screw or clamp a 2x4 (or other straight edge) to onto plywood; register the edge of your circular saw against the straight edge, and you'll get just as good results ripping as you do from most small job site table saws. Just takes a little more work to set everything up.

Last edited:

Jarick

Rock Star

- Messages

- 5,004

Sounds like you've got a plan. For future reference:

Screw or clamp a 2x4 (or other straight edge) to onto plywood; register the edge of your circular saw against the straight edge, and you'll get just as good results ripping as you do from most small job site circular saws. Just takes a little more work to set everything up.

Oh that's a really clever solution. I need to get a table saw and miter saw at some point anyway. I got a circular saw for the first time last year, and it has a laser guide which is helpful, but yeah a piece of wood clamped down would work well as a guide.

MirrorProfiles

Rock Star

- Messages

- 4,899

Well, I bought an MA-1 measurement mic which I used for about a week with the ATC's. The difference was just incredible and I couldnt get the thought of a fully integrated Neumann system out of my head. So the ATC's are out and these are in.

they big. until today I thought people who described speakers as breathtaking were just being cunts. But this really is something else (and they offer a nice contrast to my nearfields.

Genuinely think the difference between KH80 or 120 with a sub and measurement mic and these 420's wouldn't be enormous, especially for most people's needs. I really like Sonarworks but this is just a whole level beyond.

they big. until today I thought people who described speakers as breathtaking were just being cunts. But this really is something else (and they offer a nice contrast to my nearfields.

Genuinely think the difference between KH80 or 120 with a sub and measurement mic and these 420's wouldn't be enormous, especially for most people's needs. I really like Sonarworks but this is just a whole level beyond.

Last edited:

TJontheRoad

Shredder

- Messages

- 1,214

Cool. Did you rotate the tweeter and mid speaker for sideways mount?Well, I bought an MA-1 measurement mic which I used for about a week with the ATC's. The difference was just incredible and I couldnt get the thought of a fully integrated Neumann system out of my head. So the ATC's are out and these are in.

View attachment 22460

they big. until today I thought people who described speakers as breathtaking were just being C*nts. But this really is something else (and they offer a nice contrast to my nearfields.

Genuinely think the difference between KH80 or 120 with a sub and measurement mic and these 420's wouldn't be enormous, especially for most people's needs. I really like Sonarworks but this is just a whole level beyond.

MirrorProfiles

Rock Star

- Messages

- 4,899

Yep. My desk is a bit big and having the 420's vertical would put the tweeter at an awkward height, or the speakers would just be firing into the desk. First time I actually heard 420's was in Manny Marroquins room at Larrabee (not that he used them), but they were oriented on their side and it took me a while to realise its the same speaker as they're usually done vertically.Cool. Did you rotate the tweeter and mid speaker for sideways mount?

really easy to rotate, just 4 screws and making sure its sealed right.

TJontheRoad

Shredder

- Messages

- 1,214

Since I had great success with the Neumann system, I decided to try the IK ARC Studio system with my old Event PS6 monitors. Interestingly, the test results I got were very close to the Neumann measurements. Difference mainly being the more extreme dip at about 75Hz. I think this can attributed to the Events being placed on top of the Neumanns and are firing in a more downward direction.

Last edited:

MirrorProfiles

Rock Star

- Messages

- 4,899

been somewhat at war with a 50hz axial mode and figured I'd try and tackle it. Things sort of timed in a weird way where I've ended up with 10 huge ass soffit bass traps (4 that are 40cm x 40cm x 110cm, 6 that are 60cm x 60cm x 110cm). Prior to that I had quite a lot of bass traps but the wall coverage has gone up substantially in the last week.

The green curve was before, you can see the 47hz dip at listening position. With the new panels in, its basically completely smooth there now (a good 10dB louder at that frequency).

Neumann's correction curve is working way less hard in the low end now (ignore how crazy the subs look - they fire out the sub at max volume so the correction is mostly cutting as you get better headroom that way).

BEFORE:

AFTER:

and you can see the spectogram here:

share.icloud.com

share.icloud.com

The green curve was before, you can see the 47hz dip at listening position. With the new panels in, its basically completely smooth there now (a good 10dB louder at that frequency).

Neumann's correction curve is working way less hard in the low end now (ignore how crazy the subs look - they fire out the sub at max volume so the correction is mostly cutting as you get better headroom that way).

BEFORE:

AFTER:

and you can see the spectogram here:

iCloud Photos - Apple iCloud

View, organize, and share photos and videos with iCloud Photos on the web. Changes will sync across your devices with iCloud.

Last edited:

![04262024 MA 1 Alignment [Corrected].png](/data/attachments/22/22100-998af5ba26fde5a71218936ed10bad0a.jpg?hash=mYr1uib95a)

![04262024 MA 1 Alignment [intial].png](/data/attachments/22/22099-2ac4bacba424a7ee674fb0d6f72307b3.jpg?hash=KsS6y6Qkp-)