I thought I’d share some recent recording-related projects I finished. After completing these, I can move my focus back to some guitar-related DIY.

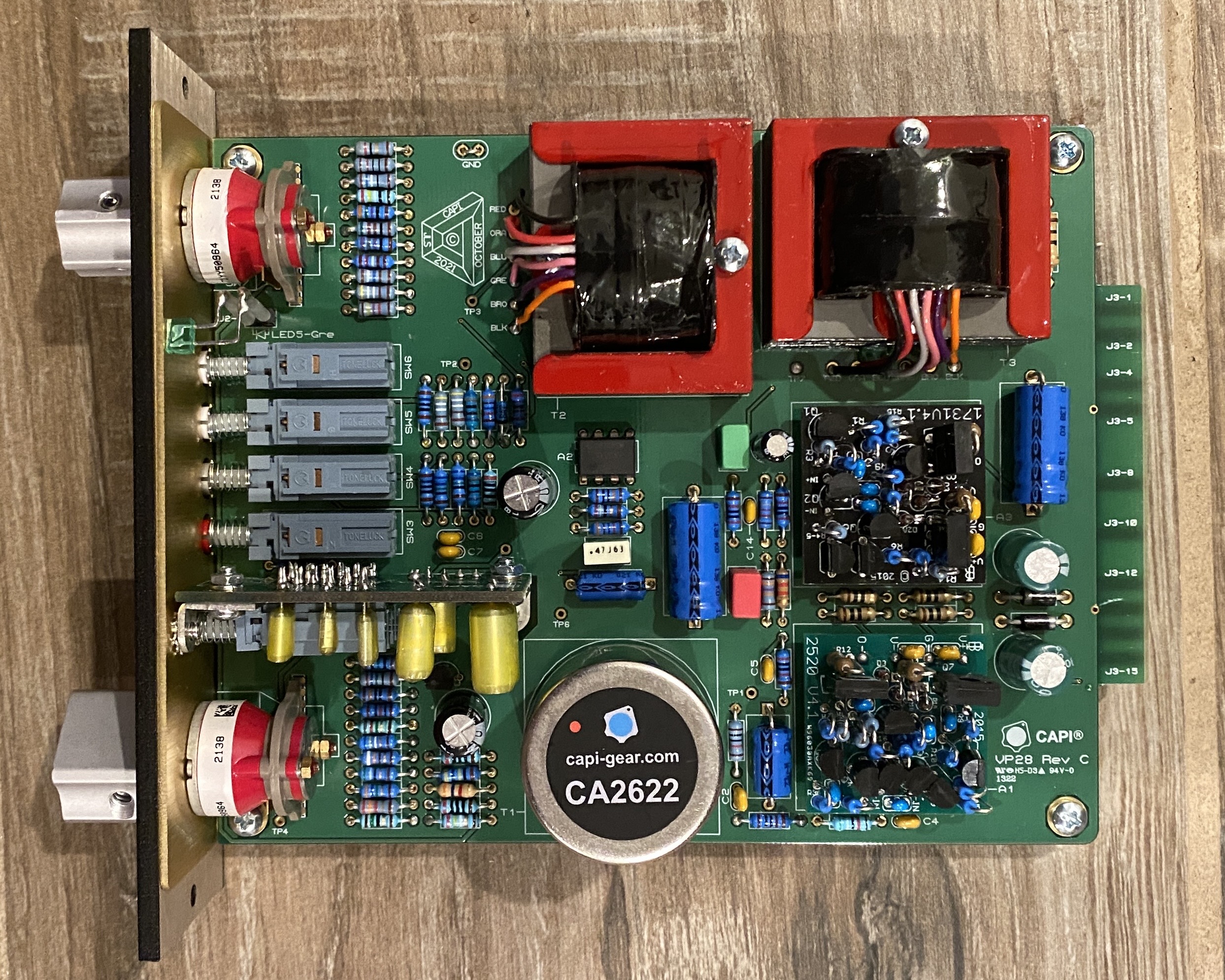

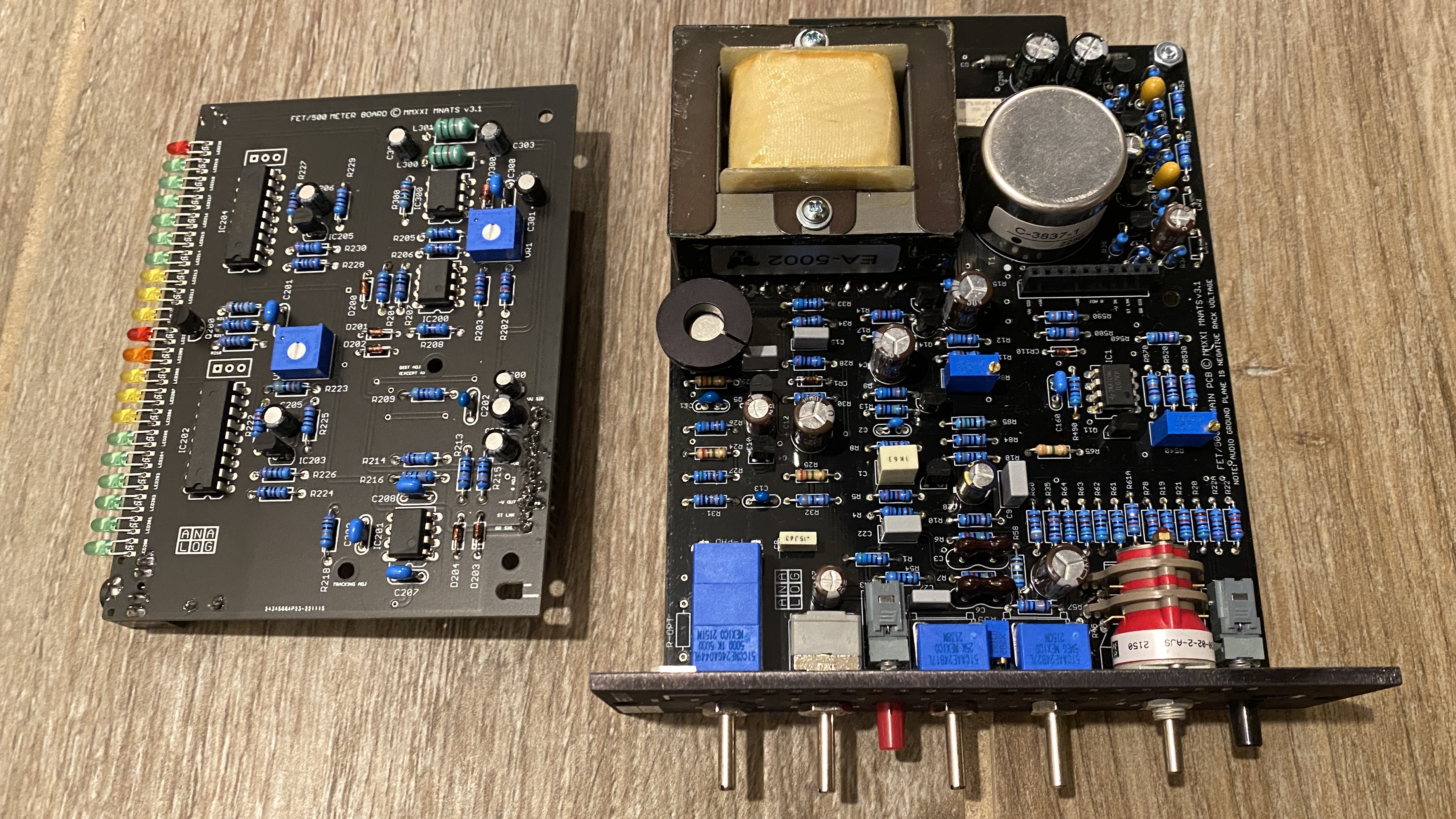

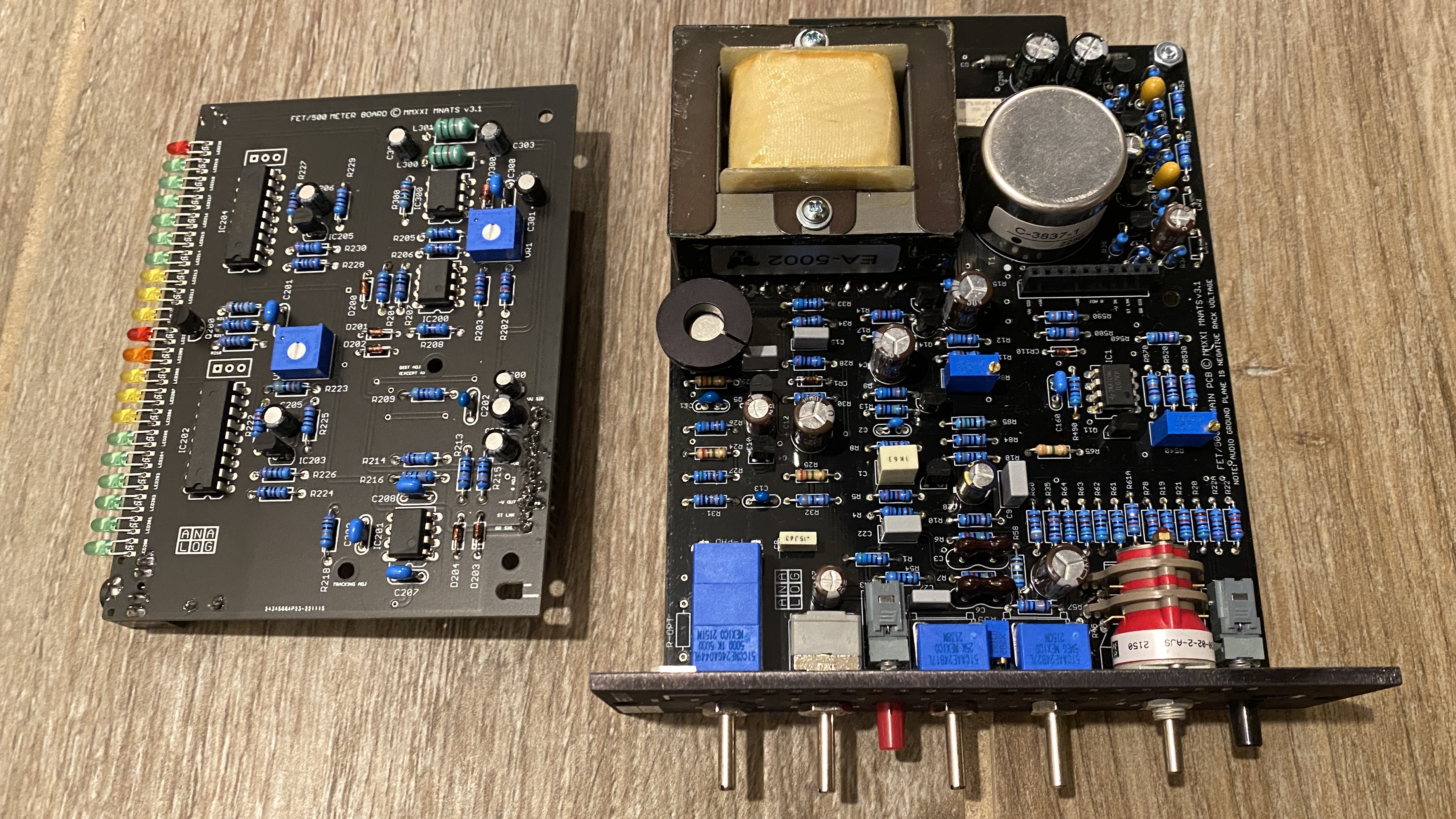

I finished a Hairball FET/500 Rev D kit at the end of January. It’s a 500-series adaption of an 1176 compressor that goes into a lunchbox power supply. The concept is kind of like the Synergy or Eurorack modules for those unfamiliar. I’ve been using this module for the 1176 sound on drums, although I’d like to run some clean guitar and bass through it one of these days. I had the kit unbuilt since November prior to working on it.

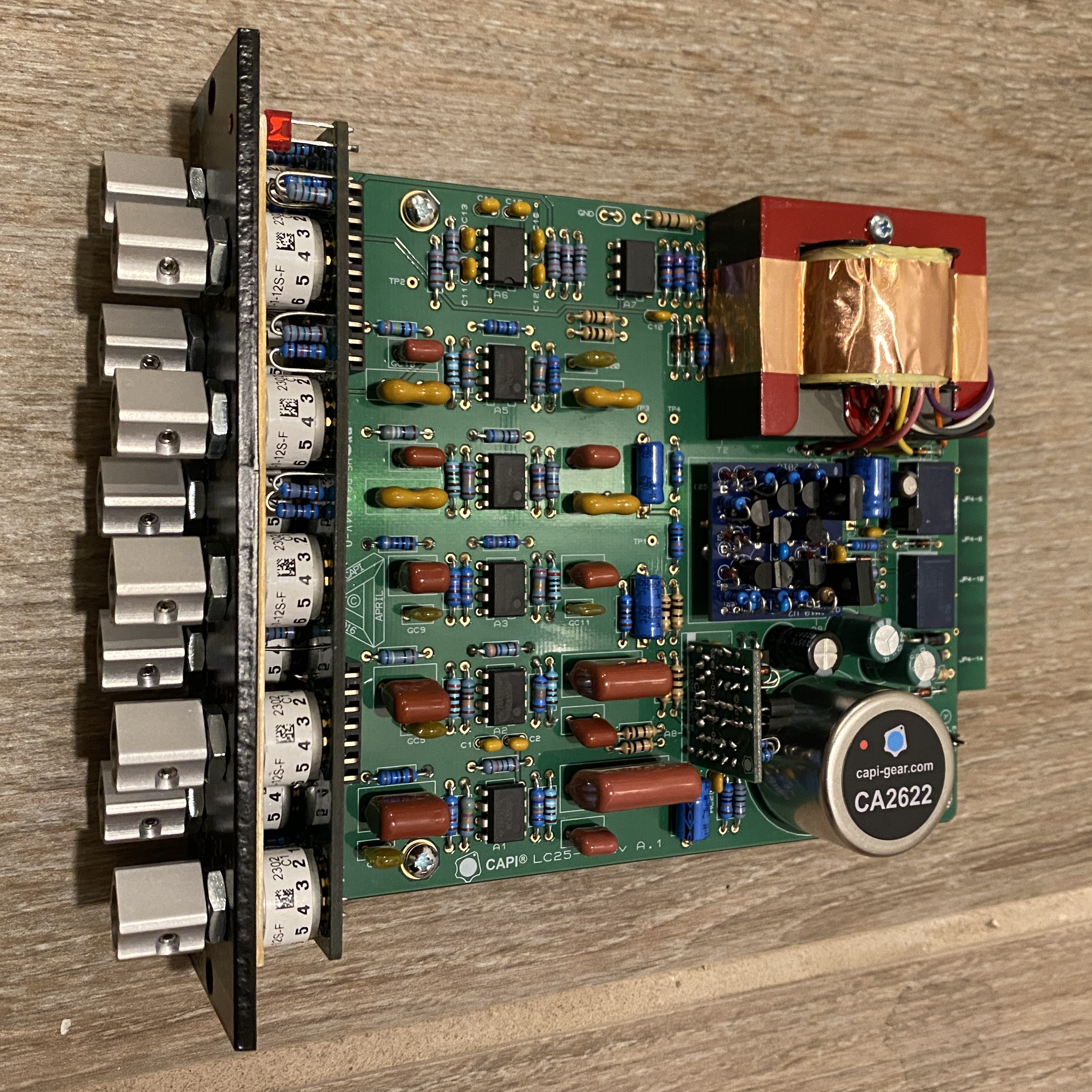

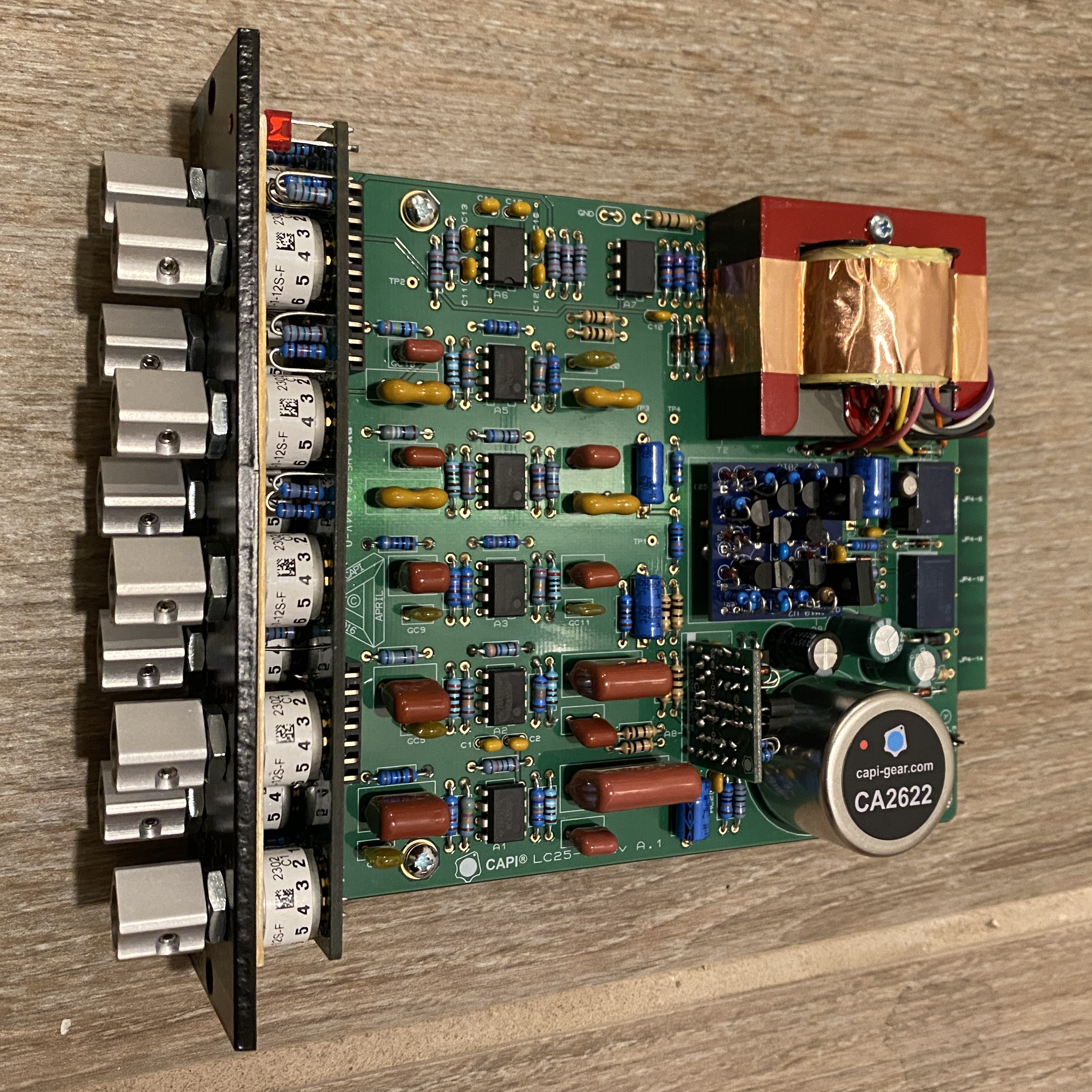

At the end of February, I built a CAPI LC25 EQ kit. It’s based on an API 560 Graphic EQ, but with frequencies based on a Urei 535 Graphic EQ. I wanted to have a hardware EQ to pair with the Hairball FET/500 to process drums like kick and snare. It has a set 10 bands, and boost/cut is done in fixed 2dB steps.

The API-based circuits use discrete op amps (the little square PCBs on the LC-25). CAPI offers kits of those op amps, and they are about the hardest thing to solder that I’ve come across. They are typically about 10 transistors, 10 resistors, and 5 capacitors on a 1”x1” PCB.

The DIY modules for 500-series lunchboxes are a relatively inexpensive way to try inspired-by classic audio circuits, without having to absorb the cost of individual power supplies and rackmount enclosures. It’s been fun playing around with this hardware because I’m not fussing about the exact frequency or dB level down to the decimals as I would with plugins.

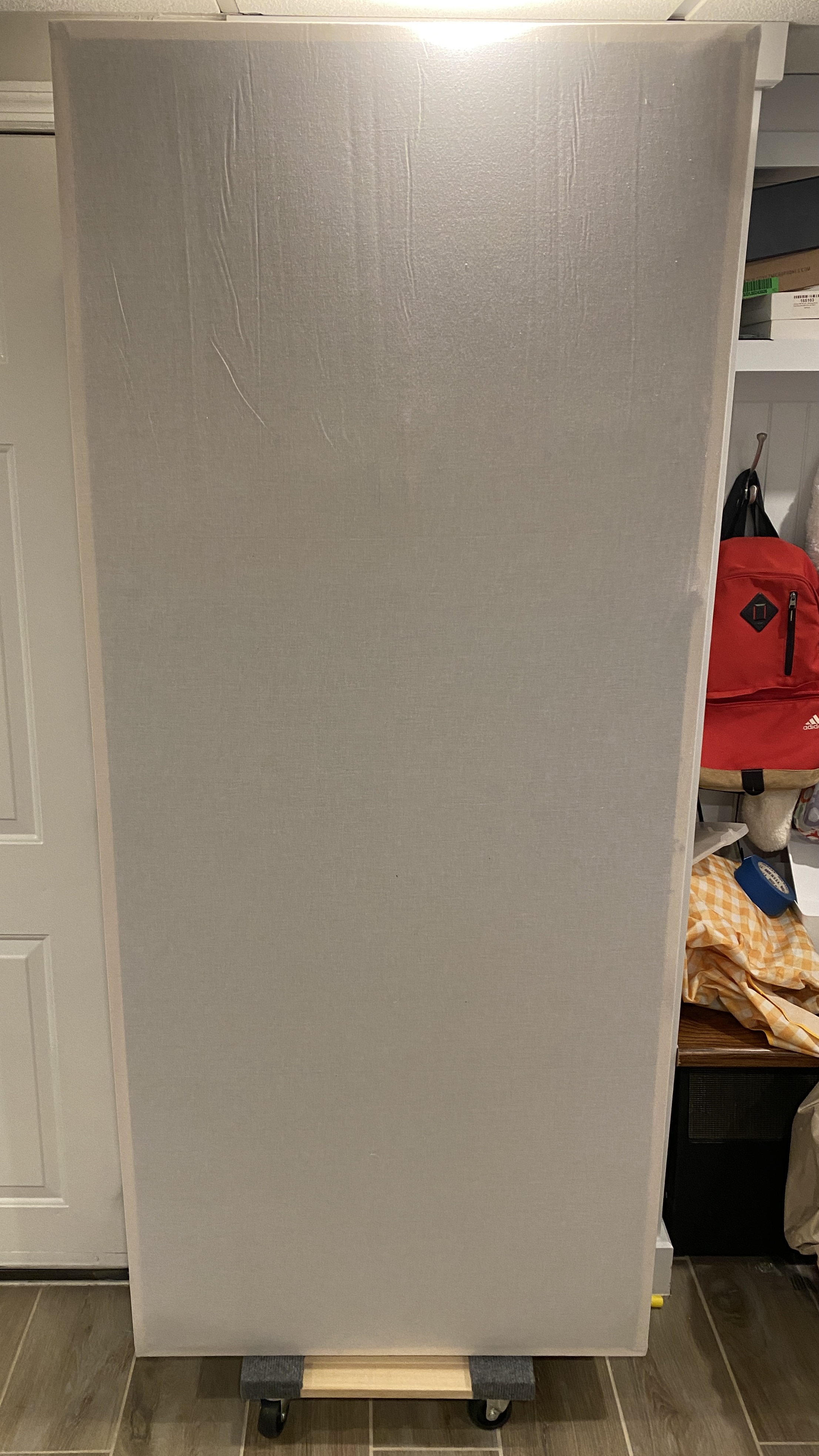

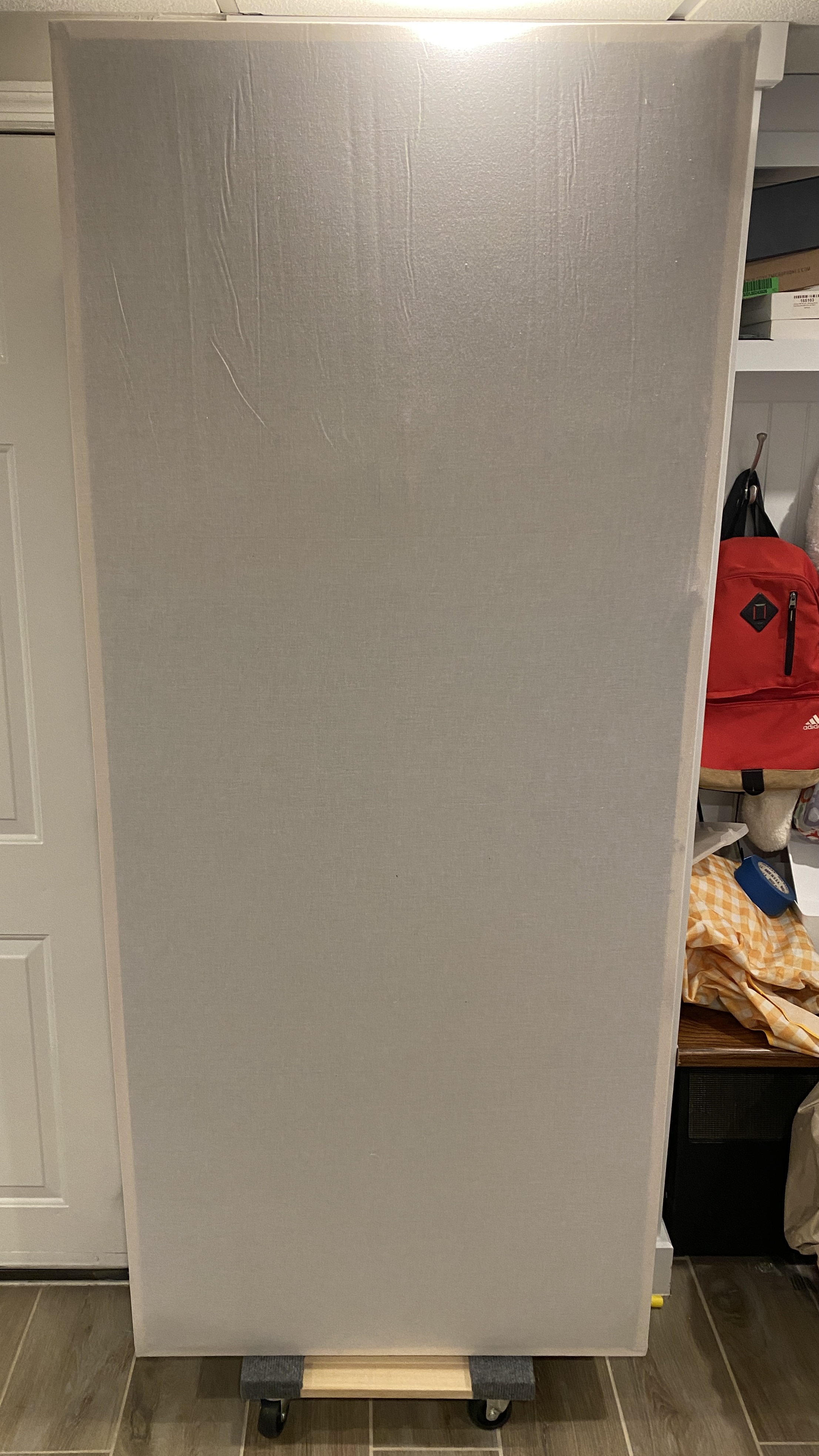

I also built 2 absorptive panels last week. I’m not particularly good at woodworking, but building my own panels has been a good start. Lately, I’ve been making my frames 32”w x73.5”h x7”d, so I can stuff 4 sheets of Rockwool Safe N Sound on and fill the rest with R19 fluffy fiberglass. The panels have helped cut down on some nasty reflections in the room.

The above picture is a frame covered with 1 layer of unbleached muslin fabric. I will cover with another layer eventually, to minimize the contrast between the wood and the insulation. I didn’t want to drill into my walls to support panels, so I’ve found that putting these big panels on Home Depot dolly carts has been most useful to me.

I finished a Hairball FET/500 Rev D kit at the end of January. It’s a 500-series adaption of an 1176 compressor that goes into a lunchbox power supply. The concept is kind of like the Synergy or Eurorack modules for those unfamiliar. I’ve been using this module for the 1176 sound on drums, although I’d like to run some clean guitar and bass through it one of these days. I had the kit unbuilt since November prior to working on it.

At the end of February, I built a CAPI LC25 EQ kit. It’s based on an API 560 Graphic EQ, but with frequencies based on a Urei 535 Graphic EQ. I wanted to have a hardware EQ to pair with the Hairball FET/500 to process drums like kick and snare. It has a set 10 bands, and boost/cut is done in fixed 2dB steps.

The API-based circuits use discrete op amps (the little square PCBs on the LC-25). CAPI offers kits of those op amps, and they are about the hardest thing to solder that I’ve come across. They are typically about 10 transistors, 10 resistors, and 5 capacitors on a 1”x1” PCB.

The DIY modules for 500-series lunchboxes are a relatively inexpensive way to try inspired-by classic audio circuits, without having to absorb the cost of individual power supplies and rackmount enclosures. It’s been fun playing around with this hardware because I’m not fussing about the exact frequency or dB level down to the decimals as I would with plugins.

I also built 2 absorptive panels last week. I’m not particularly good at woodworking, but building my own panels has been a good start. Lately, I’ve been making my frames 32”w x73.5”h x7”d, so I can stuff 4 sheets of Rockwool Safe N Sound on and fill the rest with R19 fluffy fiberglass. The panels have helped cut down on some nasty reflections in the room.

The above picture is a frame covered with 1 layer of unbleached muslin fabric. I will cover with another layer eventually, to minimize the contrast between the wood and the insulation. I didn’t want to drill into my walls to support panels, so I’ve found that putting these big panels on Home Depot dolly carts has been most useful to me.

Last edited: